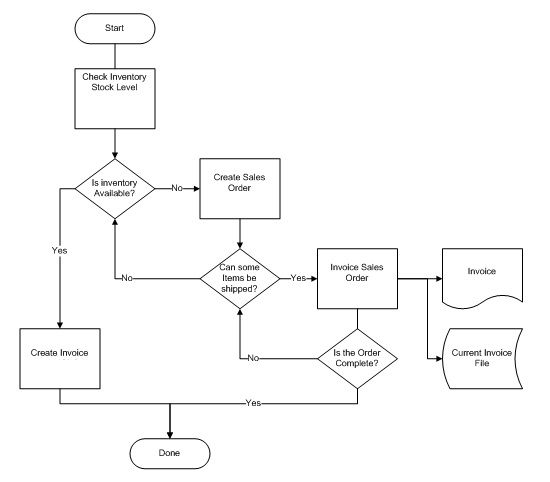

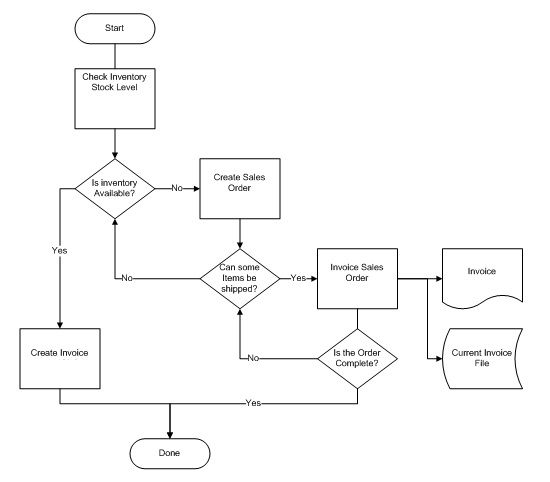

The Order Entry process is best suited to firms where:

When entering the order, the order can be printed at that time

in order to give the customer a copy, or it can be printed

later.

When the order is printed, it is called a Picking Ticket.

This allows staff to pick the items ordered off the shelf and

assemble the order for billing.

If the order was not printed when it was entered in Sales Orders, it can be printed later using

Print Picking Tickets.

With this approach several orders can be entered at one time and

then printed as a batch. This may be useful if the printer is

currently busy or otherwise unavailable.

As the staff assemble the order, they can manually mark on the

Picking Ticket the quantity actually pulled from the shelf

(Qty Shipped), and note the serial numbers.

They can also manually mark the quantity back ordered (i.e.

quantity currently unavailable).

Once the Picking Ticket has been completed and the order

assembled, the order can be billed using Bill

Sales Order.

If staff is unable to ship any of the goods, this program can also

be used to indicate that these items are on back order.

When the order is billed, apply any deposit received on the order

against the resulting invoice.

After the order has been billed, the invoice prints out.

Any goods not shipped are assumed to be back ordered. (If all items

were back ordered, no invoice is created.)

To make corrections to the invoice, use Sales

Order Invoice in Change mode.

The invoice can be reprinted using Print Sales

Order Invoice.

Negative product quantities can be entered on Sales Orders so goods can be returned to stock and credit invoices generated.

Sales Orders respect any Suggested Sales List assigned to the product that is entered on the order.

Note: As an alternative to using the Sales Order and Picking Ticket to fill orders, refer to Sales Order Invoices for an outline on the one-step process.

Note: Changes to back order Sales parts details on the resulting Sales Order Invoice also update the Sales Order and the Drop Ship Purchase Order details.

Refer to Purchase Order from Sales Order Overview for details on this feature and the process flow.

Start-Up Preparation:

Before using the Order Entry programs, setup the required tables

outlined in OE Start-Up Sequence.

| Converted from CHM to HTML with chm2web Pro 2.85 (unicode) |